- Call Us

- +86 133 0629 8178

- tonylu@hexon.cc

- videos

- images

current video

Related videos

36300004

36300004-5

36300004-4

36300004-3

36300004-2

36300004-1

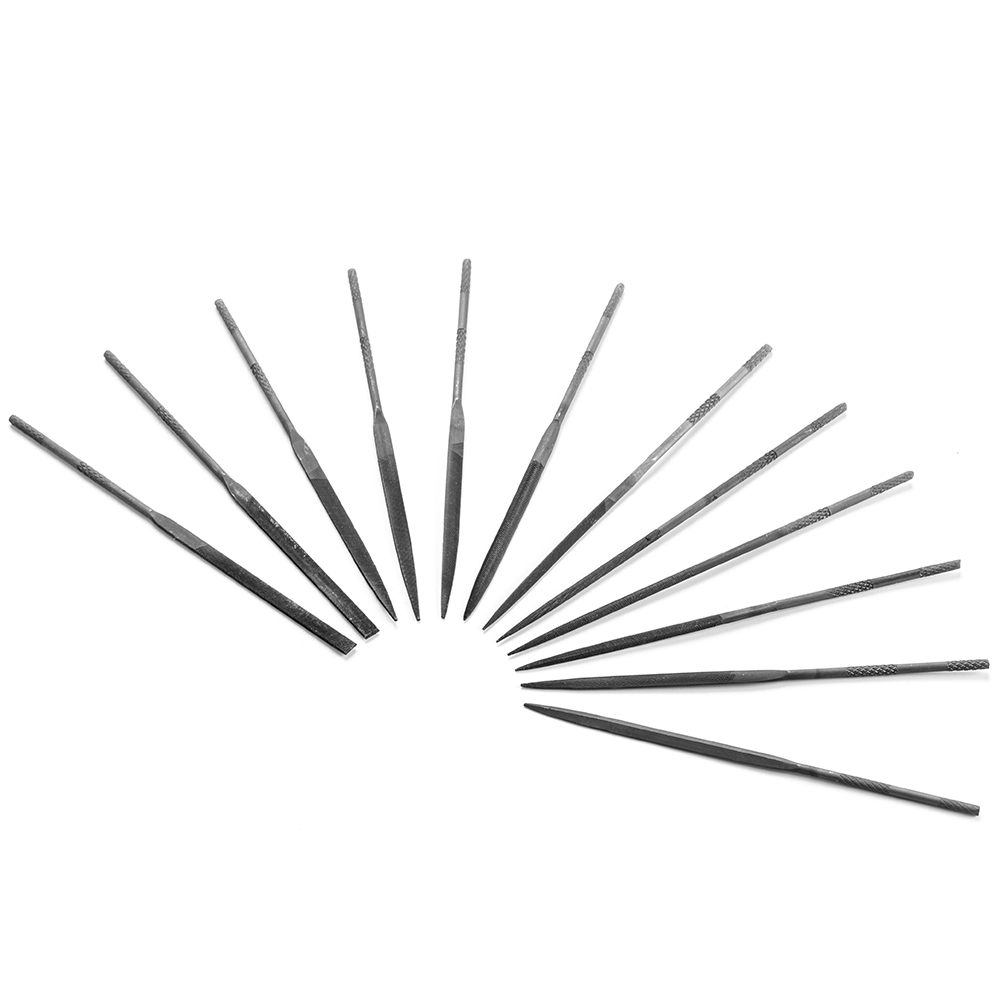

Features

Surface nickel plated: the overall surface is bright, with rust prevention effect, the files are not easy to rust.

Forged with 45 # steel: made of high-quality steel, with high hardness, wear resistance and durability, and not easy to deform.

High temperature quenching treatment: the filse has high toughness and hardness, excellent workmanship, corrosion resistance,fine sand grains.

Specifications

|

Model No |

Type |

|

360050001 |

Round files 200mm |

|

360050002 |

Square files 200mm |

|

360050003 |

Triangle files 200mm |

|

360050004 |

Half round 200mm |

|

360050005 |

Flat files 200mm |

Product Display

Application of hand files

Hand files is suitable for mold polishing, deburring, edge trimming and chamfering, wood polishing, etc. It is widely used.

Precations when using steel files:

1. Do not use a new file to file hardened and super hard metals;

2. Do not file the oxide layer of the workpiece with a file. The hardness of the oxide layer is high, and the file teeth are easy to be damaged. The oxide layer can remove with grinding wheel or chisel. Quenched workpiece can be processed with diamond file. Or make the workpiece first. After annealing, the file can be used for filing.

3. Use one side of the new file first, and then use the other side after the surface is blunt,

4. In the whole process of using the file, always use a copper wire brush (or steel wire brush) to brush along the direction of the file tooth lines.Remove the iron filings embedded in the tooth socket. After use, carefully brush off all the iron filings before storing them.

5. The file should not be used too fast, otherwise it is easy to wear out prematurely. The best frequency of file round-trip is 40Times/minute, the length of the file accounts for 2/3 of the total length of the file tooth surface.